Fiberglass Application, Mold Making, and Sculptural Fabrication

-

GlasCraft INDy chopper/gelcoat system

Operating fiberglass chopper to fabricate mother shell for a large silicone mold.

-

Water Park in Albuquerque, NM

Mold for a decorative piece fabricated for a water park in New Mexico.

-

Decorative piece for Albuquerque Water Park

Painting

-

Bass Pro Shops Tree: Fiberglass hand layup

Laying several layers of fiberglass on a tree silicone mold after a tinted gelcoat had been applied. One of the many processes required to fully manufacture each Bass Pro Shops Tree.

-

Bass Pro Shops Tree: the final product

-

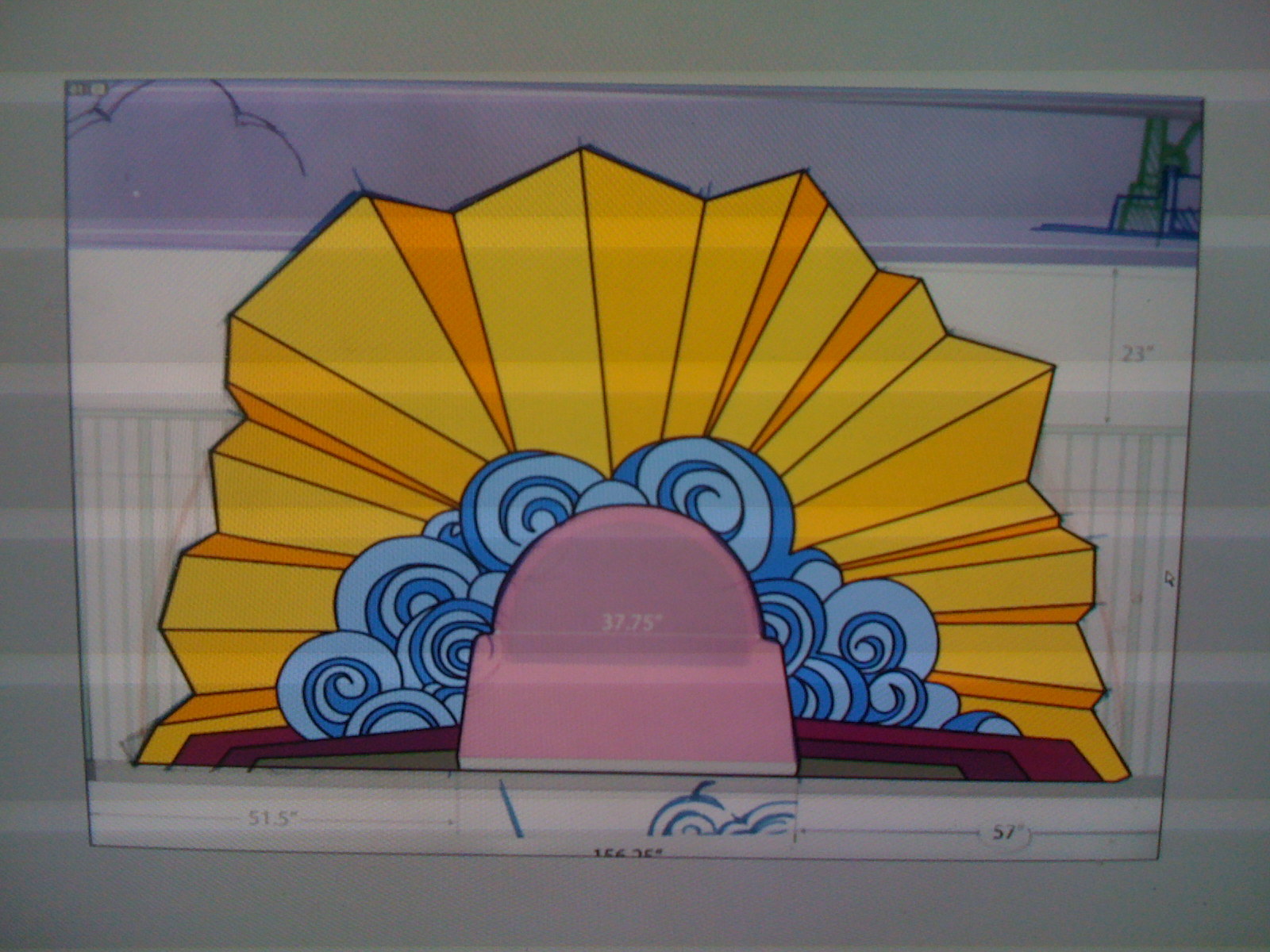

Slide Backer for Albuquerque Water Park

Slide backer prototype drawing. Photoshop

-

Slide Backer work in progress

Styrofoam sculpting and hot wire milling.

-

Slide Backer for Albuquerque Water Park

Finished piece.

-

The Limited decorative frame

Preparing to make a silicone mold.

-

The Limited decorative frame

Pouring silicone to create the mold.

-

Latter half of matrix mold sculpted in Wed clay, ready for fiberglass application.

-

Fiberglass

Hand laying fiberglass with UV activated laminating resin.

-

1630 and silicone

1630 rat case mold run in tin cure silicone.